It's Time to Find a Way Forward With Industry 4.0

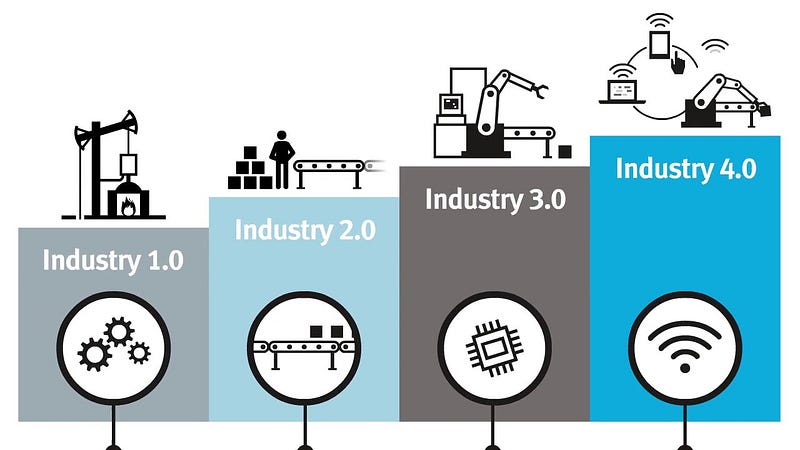

Industry 4.0 is the dynamic advance in an assembling organization’s computerized change development bend, concentrating on joining data innovation and operational innovation to modernize the worth chain in new manners.

industry-4.0

Ananth Info is one of the main Industry 4.0 advancements that are filling business development for producers. In basic terms, the Industrial Internet of Things (IIoT) is a system that interfaces various mechanical machines along with the assistance of sensors, gadgets, programming, and the internet. Industrial machines that are associated together through the web incorporate robots, sensors, cranes, blowers, and then some.

For our assembling clients, IIoT empowers far off availability, checking, and prescient support of their machines on the shop floor. Cloud, associated gadgets, sensors, computerized reasoning, huge information, digital security, and added substance fabricating, are a couple subcomponents of their IIoT technique. With the assistance of interconnected frameworks, sensors, and gadgets, their assembling workforce can get to the machines from their office, evaluate their presentation, and view experiences just as log documents distantly — whenever, anyplace.

Any variety or aberrance from the set boundaries can be distinguished by keen machines and conveyed to those liable for working it. Additionally, smart sensors help computerize the dynamic procedure on the shop floor.

At the point when you introduce another brilliant machine, it ought to be perfect with the current arrangement and machines from the OEMs. Likewise, solid availability between the gadgets empowers information sharing, builds up prescient support, and limits security dangers.

Mechanical apparatus regularly requires visit support. Fortunately with IoT-empowered ERP frameworks, makers can preemptively know and foresee when the operational disappointment of the mechanical machine is inescapable utilizing sensors and cloud-based investigation.

Large parts in assembling, for example, Boeing, Bosch, Airbus, and so forth depend on IIoT for different reasons. Airbus has propelled an activity: Factory of the Future that centers around wearable innovation and coordinated sensors which are intended for wellbeing and diminished mistakes. Bosch propelled a track and follow program that robotizes processing plant tasks, tracks the laborers, and aides get together activities.

Cloud is a supreme part of IIoT-empowered ERP

The significant target of cloud ERP and IIoT is expanding authoritative effectiveness. We definitely realize that IIoT is a structure of keen machines with installed sensors and system network. Cloud permits this structure to gather, send, and get information with no manual intercession.

Cloud ERP and IIoT run corresponding with one another. While IIoT produces a huge measure of information, cloud ERP makes a pathway for it to travel and arrive at its goal. Regardless of whether it is tied in with following the information created from machines or about realizing what number of items have been acquired and dispatched, cloud ERP lets you see everything from a solitary stage. In straightforward words, IIoT creates urgent information for the association, and cloud ERP smoothes out and ensures it. A Gartner research says that IoT’s quickly developing advancements have introduced inventive interruptions at an amazing pace, in five key zones:

Sensing — IoT endpoints

Communicating — IoT correspondences

Making sure about — IoT security

Understanding — IoT information and examination

Acting — IoT man-made consciousness (AI)

Source: Gartner

Incorporating ERP with IIoT prompts information accessibility continuously. Incorporating ERP programming with IIoT changes the gracefully chain definitely. How? When IIoT gadgets converses with your ERP applications, it advances perceivability at a nitty gritty SKU level. For instance, when you realize that parts you require for creation are to be delivered universally, ERP permits you to follow the hour of appearance as items are labeled and you get steady data of its whereabouts. ERP and IIoT applications cooperate to change the manner in which data is being gotten by us. It lets you screen gear and the creation line day in and day out.

Cloud is the passage to present day producing. It permits makers to get to data about the working of items after they have been sent to the clients. Makers can screen the item’s conduct, its support, mileage, and take care of any difficult that happened in the item distantly.

How mists ERP Enable IIoT in Manufacturing

Cloud ERP establishes the framework for coordinated effort, mechanization, and expanded productivity in an assembling situation. At the point when you tie cloud ERP with keen mechanical gadgets, it lets you see an all encompassing perspective on the shop floor and access information from anyplace and through any web empowered gadget.

IIoT basically covers all industry parts where mechanical machines are utilized. It gets simpler for producers to check the boundaries, upkeep plan, get together procedure, and advance various parts on the shop floor.

Cloud ERP gets each piece of data a solitary framework. With coordinated IIoT, makers can all the more completely see bookkeeping subtleties, creation finishing status, stock levels, client input, deformity (assuming any), shipment timetable, and minor subtleties of everything occurring on the shop floor.

Comments

Post a Comment